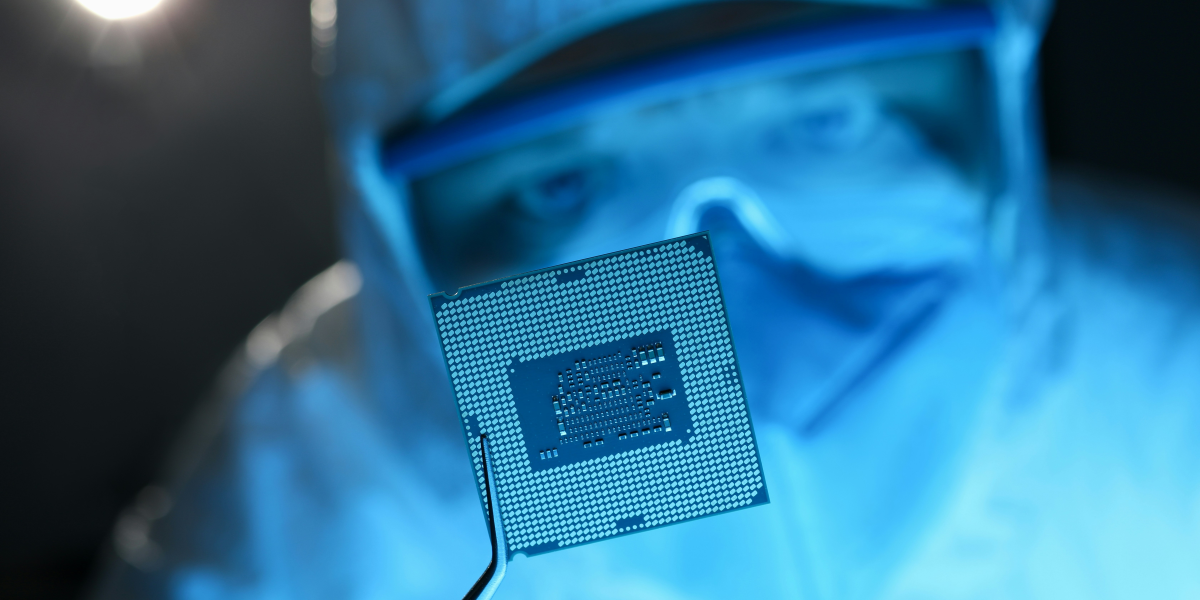

In today’s technology-driven world, semiconductor chips are essential components in everything from smartphones to cars and medical devices. However, producing these chips requires a complex, global supply chain that involves numerous steps, from raw material sourcing to manufacturing and distribution.

The Role of Semiconductor Chips in Modern Technology

Semiconductor chips, often called the “brains” of electronic devices, are critical to powering modern technology. As demand for smart devices and electronics grows, so does the need for efficient chip production and distribution.

Why Semiconductor Chips Are Essential

Semiconductors power information processing, data storage, and complex calculations across industries like electronics, healthcare, automotive, and telecom. As these sectors grow, so does the demand for advanced chips, intensifying the global focus on strengthening production and supply.

Growing Demand and the Supply Chain Strain

Rising semiconductor demand has strained the global supply chain. Smartphone, electric vehicle, and data center companies rely on a steady chip supply to meet production goals. Disruptions can lead to delays across industries, highlighting the need for a resilient supply chain.

Key Stages in the Chip Manufacturing Supply Chain

The semiconductor supply chain is complex, involving multiple stages, from raw material sourcing to the final distribution. Each stage requires specific resources, equipment, and expertise, creating unique challenges.

Raw Material Sourcing and Processing

Semiconductors are primarily made from silicon and sourced globally. Mining, refining, and processing silicon is complex, requiring advanced machinery and skilled labor. Disruptions in raw material sourcing can impact the entire chip manufacturing process, emphasizing the need for stability.

Fabrication and Assembly

Once the raw materials are processed, chip fabrication begins. This stage involves transforming silicon wafers into chips through processes like lithography, etching, and layering. Fabrication requires specialized facilities called “fabs” and advanced equipment, making it capital-intensive. After fabrication, chips are assembled and packaged to ensure durability and functionality in various environments.

Testing and Quality Control

Quality control is essential in chip manufacturing, as even minor defects affect performance. Chips undergo rigorous testing for flaws, functionality, and reliability before reaching the market. High testing standards reduce faulty chips, improving device dependability.

Challenges Facing the Chip Manufacturing Supply Chain

The chip supply chain faces multiple challenges, including geopolitical tensions, limited manufacturing capacity, and environmental factors. These issues can disrupt production and delay delivery, affecting industries globally.

Geopolitical and Trade Tensions

The semiconductor industry is heavily influenced by international relations, with key players across the United States, China, Taiwan, and South Korea. Trade restrictions, tariffs, and regulatory changes can create significant obstacles, impacting raw material access, fabrication, and distribution. Geopolitical issues require companies to develop strategies for navigating complex trade environments.

Limited Manufacturing Capacity

Building and maintaining fabrication facilities is expensive, and only a few companies can produce chips at the scale needed to meet global demand. Limited manufacturing capacity makes the supply chain vulnerable to disruptions and delays. Many tech companies have responded by investing in their own production facilities or forming partnerships to secure a steady chip supply.

Environmental and Resource Constraints

Chip manufacturing requires significant energy and water, which creates environmental concerns, especially as companies face pressure to reduce their carbon footprints. Access to sustainable energy sources and efficient water usage practices is becoming essential in ensuring an eco-friendly and resilient supply chain.

Strategies for Strengthening the Chip Supply Chain

To address these challenges, companies are implementing strategies to build a more resilient and reliable supply chain. From diversifying suppliers to advancing technology, these strategies are crucial for minimizing disruptions.

Supplier Diversification and Nearshoring

Companies are diversifying their supplier base to reduce dependency on single regions. By sourcing raw materials and manufacturing from multiple locations, businesses can better manage risks from geopolitical tensions and local disruptions. Nearshoring—moving parts of the supply chain closer to home—also helps reduce logistical complexities and improve response times.

The Future of Chip Manufacturing: Moving Toward Sustainability and Resilience

As demand for semiconductors rises, the industry is focusing on creating a sustainable and resilient supply chain that meets global needs while minimizing environmental impact.

Embracing Sustainable Practices

With rising awareness of environmental impact, the chip manufacturing industry is working toward sustainability. Companies are exploring ways to reduce energy and water consumption in production processes and investing in green technologies. Embracing sustainable practices not only aligns with global environmental goals but also strengthens brand reputation.

Building a Resilient Future

To ensure stability, companies are enhancing resilience by diversifying production, advancing technology, and planning for supply disruptions. A robust supply chain enables the industry to meet global demand and maintain a steady supply of semiconductor chips for essential technology.

How to Develop a Resilient Semiconductor Supply Chain

The semiconductor supply chain is complex, requiring careful planning and adaptability. By diversifying suppliers, investing in sustainability, and embracing innovation, companies can secure a steady chip supply to meet tech demand. A resilient, sustainable approach to chip manufacturing is crucial for long-term success as the industry evolves.

Published by: Khy Talara